TINTORIA FINISSAGGIO 2000

Activity description

TINTORIA FINISSAGGIO 2000 was founded in 1973. We started out processing knit fabrics for the sportswear industry before turning to noble fibres such as silk, cashmere and wool and these now form our core business.

More recently we have developed a range of techniques for cellulose fibres such as linen, cotton and viscose. We also produce technical products for use in the car manufacturing, furnishing and outdoor industries.

Dyeing: We dye all manner of fibres from luxurious natural fibres such as silk, wool, cashmere, and mercerised cotton to synthetic and technical fabrics such as polyester and aramid fibres.

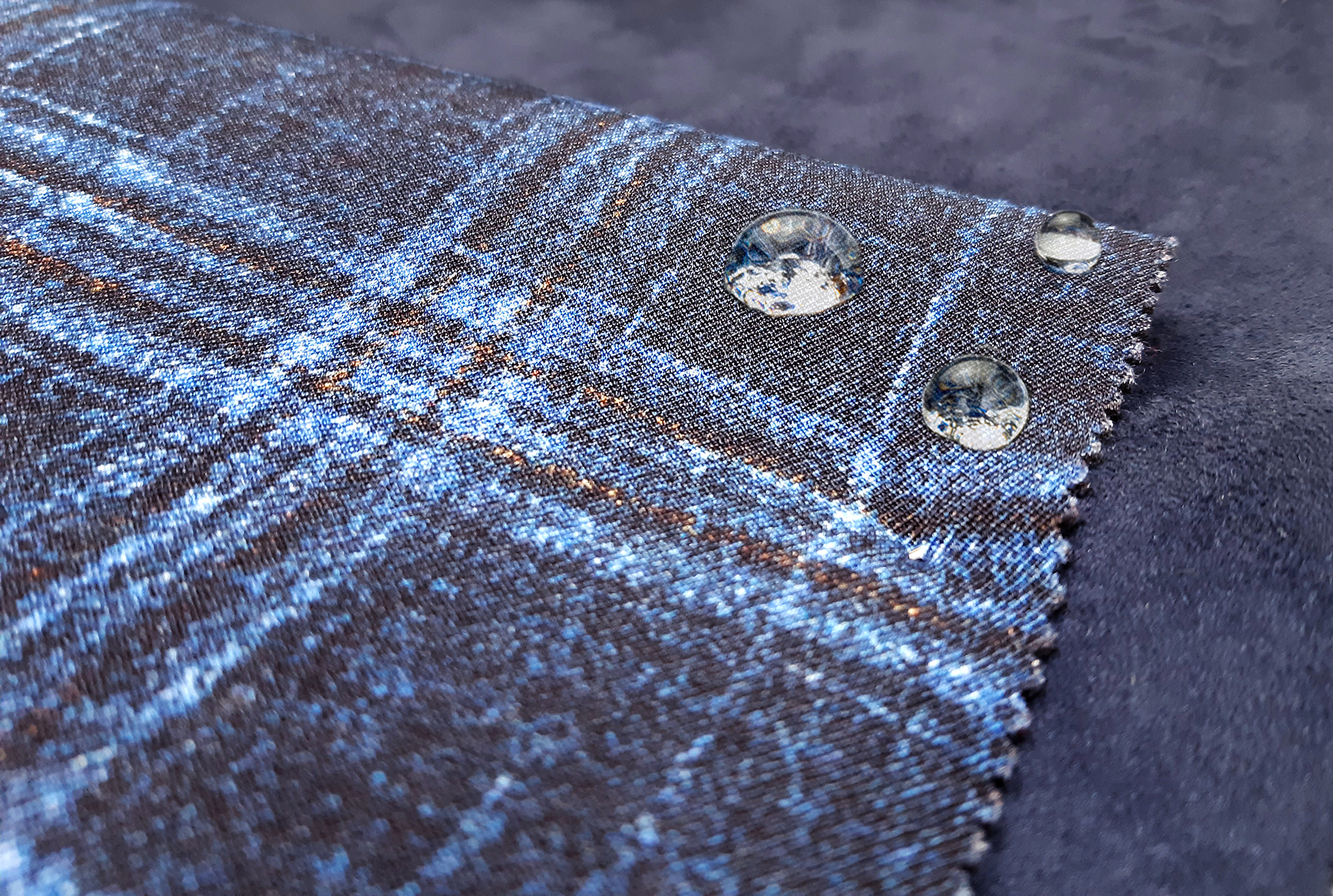

Finishing: We offer a full range of services for all fibres: raising, sueding, shearing, fulling, open width mercerizing, sanforising, continuous and discontinuous decatising, calandering, vaporisation, rope and continuous tumbling, and dry cleaning machines. Common treatments include waterproofing, softening, aloe vera, ultra dry, flame-proofing, easy care, stain proofing, ink proofing, and antistatic.

Bonding: Thanks to PUR Hotmelt adhesive technology we can now create innovative multilayer and bonded textiles that are either breathable or waterproof.

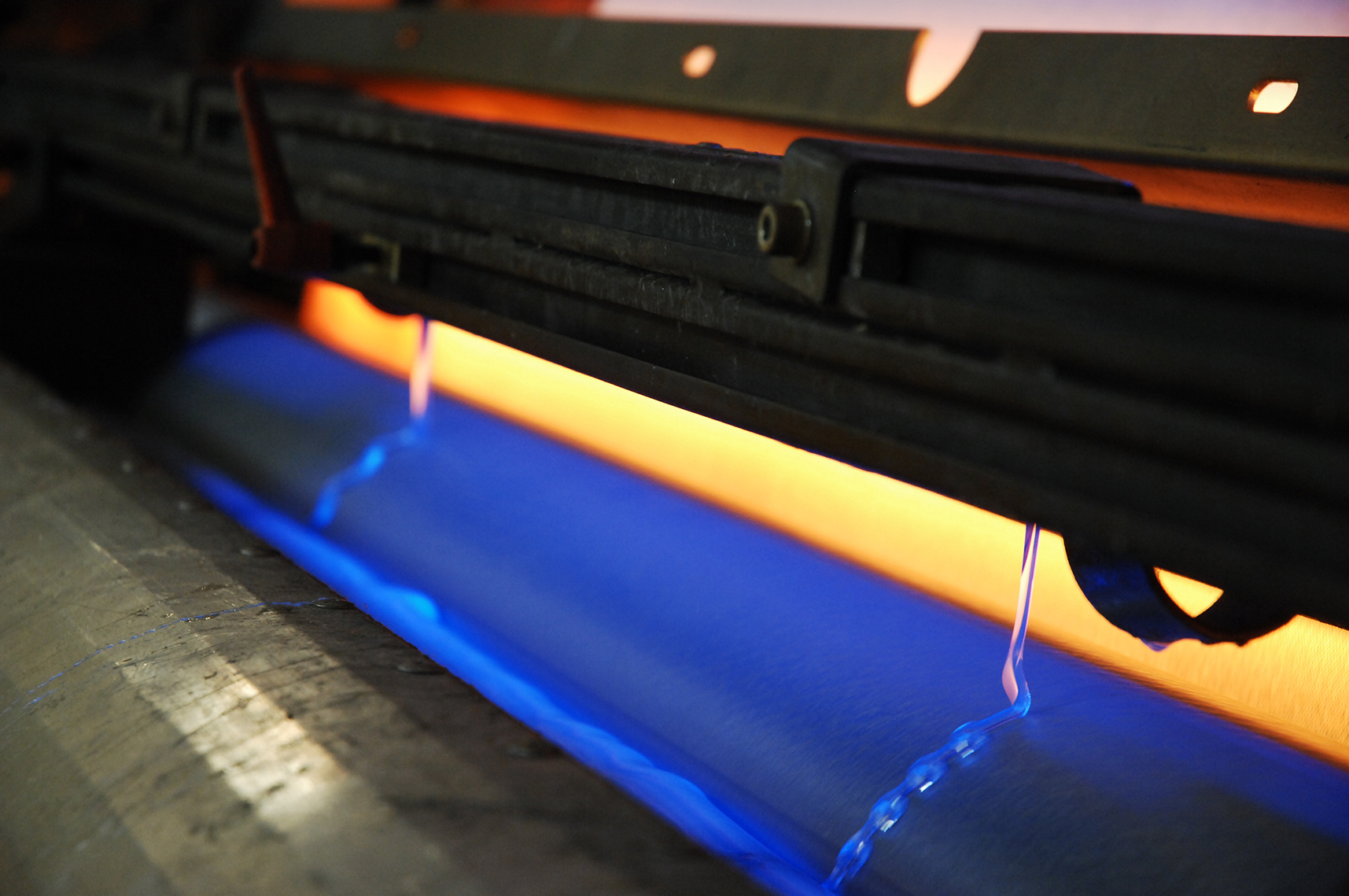

Textile printing: From design concept through its digital processing, coming to the fabric printing, we can internally manage the full path in order to ensure the best service and quality to the customer. We have two different types of printing machines, the first one is INKJET, the second one and newer is PIGMENT technology. That allows for direct printing on fabric without pre or post processing and Zero water usage, while allowing the creation of any design, in a few minutes. We develop a wide range of applications: 3D effects, white color and printing on solid dyed fabrics.

Quality control: ISO 9001 certification was obtained in 2009 and quality control plays a key role in our production process.

Product development: our clients are a source of inspiration and we always aim to reduce the distance between us.

To this end, our mission is to be more than an operational partner and to be creative and proactive in the design process as well.

Fabrics and accessories for clothing

Apparel

Outerwear

Technical

Other / Services

Textile processes (finishing, dyeing)